Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

In an era defined by rapid technological advancement and increasing demand for quality, the role of precision CNC machining services has become more crucial than ever. CNC (Computer Numerical Control) machining has long been a cornerstone of modern manufacturing, enabling the efficient and accurate production of parts across a wide range of industries. However, the future of manufacturing is being reshaped by innovations in precision CNC machining—ushering in a new age of efficiency, customization, and performance.

What is Precision CNC Machining?

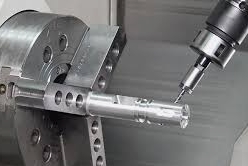

Precision CNC machining involves the use of computer-controlled tools to produce complex components with high levels of accuracy and repeatability. This process utilizes sophisticated software to direct tools such as mills, lathes, and grinders, enabling them to create parts with extremely tight tolerances. This is particularly important in industries such as aerospace, medical, automotive, and electronics, where even the smallest deviation can affect performance or safety.

Why Precision Matters More Than Ever

In today’s highly competitive manufacturing landscape, precision is not a luxury—it’s a necessity. Components are becoming smaller, more intricate, and more technically demanding. Industries require exact dimensions and flawless finishes to meet both functional and aesthetic expectations. Precision CNC machining services offer a level of control that manual operations simply cannot match, making them essential for manufacturers aiming to maintain a competitive edge.

Current Trends Shaping the Future of CNC Machining

1. Automation and Smart Factories

As Industry 4.0 gains momentum, smart manufacturing environments are integrating automation, artificial intelligence (AI), and machine learning into CNC machining. Automated systems can now monitor tool wear, adjust cutting parameters in real time, and even predict maintenance needs before failures occur. This not only reduces downtime but also enhances consistency and quality.

2. Integration with CAD/CAM Software

Modern precision CNC machining services increasingly rely on advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These platforms allow engineers to design complex parts with ease and simulate their production processes before a single piece of metal is cut. This integration helps reduce errors, shorten lead times, and ensure the design translates accurately into the final product.

3. Multi-Axis Machining

While traditional CNC machines operated on 3 axes (X, Y, and Z), the future lies in multi-axis machining—particularly 5-axis and 6-axis machines. These machines allow for greater flexibility and the ability to create highly complex geometries in a single setup. This not only saves time but also improves accuracy and reduces material waste.

4. Micro-Machining Capabilities

As industries like electronics and medical devices continue to miniaturize their products, the demand for micro-machining is skyrocketing. Precision CNC machining services are adapting to this need by offering the capability to manufacture extremely small and intricate components with unparalleled accuracy.

5. Sustainable Manufacturing

Environmental sustainability is no longer an afterthought in manufacturing. Precision CNC machining is becoming more eco-friendly through optimized tool paths, reduced energy consumption, and better material utilization. Some service providers are even using recycled materials and adopting green practices in their operations to reduce their carbon footprint.

Industries Benefiting from Advanced CNC Machining

Aerospace

Precision is critical in aerospace, where components must endure extreme conditions and comply with stringent regulations. CNC machining provides the accuracy needed for producing engine parts, airframes, and navigation systems. With the emergence of lighter materials like titanium and composites, CNC machines have evolved to handle these challenges with ease.

Medical Devices

From surgical instruments to prosthetics and implants, medical applications demand tight tolerances and high-quality finishes. Precision CNC machining is ideal for producing parts that meet FDA regulations and ensure patient safety.

Automotive

The automotive industry depends on reliable, high-volume production of intricate parts like transmission components, engine blocks, and brake systems. CNC machining ensures consistency and durability, crucial for both performance and safety.

Electronics

As devices become more compact and complex, electronics manufacturers rely heavily on micro-CNC machining for circuit boards, connectors, and enclosures. Precision ensures that each component functions seamlessly within a tightly packed system.

Challenges and Opportunities Ahead

While precision CNC machining services offer numerous advantages, they are not without challenges. The high cost of advanced machinery, a shortage of skilled labor, and the need for constant technological updates are some of the hurdles manufacturers face. However, these challenges present opportunities as well.

Investing in training programs can help bridge the skills gap and attract younger talent to the trade. Meanwhile, partnerships with software developers and research institutions can lead to the creation of smarter, more efficient CNC solutions. Additionally, the continued advancement of additive manufacturing (3D printing) is not seen as a threat but rather a complementary process that, when combined with CNC machining, opens up new possibilities in hybrid manufacturing.

Looking Forward: What's Next?

As the manufacturing world continues to evolve, precision CNC machining will play a pivotal role in shaping its future. Here's what we can expect:

Greater Customization: CNC machining will continue to support on-demand and small-batch production, allowing businesses to customize products more easily.

Increased Use of AI and IoT: Machines that communicate with each other and make real-time decisions will become the norm.

Global Accessibility: Cloud-based platforms will make it easier for companies worldwide to collaborate and access precision machining services.

Hybrid Manufacturing: Combining CNC machining with technologies like laser cutting, 3D printing, and robotic assembly will redefine how products are made.

The future of manufacturing is intricately tied to the capabilities of precision CNC machining services. As the demand for complexity, accuracy, and customization grows, CNC technology continues to rise to the occasion, driving innovation across industries. By embracing the latest trends and technologies, manufacturers can not only improve their productivity and reduce costs but also remain agile in an ever-changing marketplace. Whether you're producing aerospace components, medical implants, or automotive parts, precision CNC machining is the key to unlocking higher quality, greater efficiency, and long-term success.

About AJL Machining:

AJL Machining is a professional and industry-leading one-stop workshop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production. Our competitive edge is our ability to ensure that all of your parts are produced according to specifications, within budget, and delivered on time to meet your evolving demands. Presently, we serve over 80% of our business to multinational corporations in China, as well as overseas customers.

To learn more, please don't hesitate to contact us via email at sales@ajlmachining.com, or visit our website at www.ajlmachining.com

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: Building 5, No. 58 Chenghu Road, Kunshan Development Zone, Factory Area, West Unit, 1st Floor Workshop North and 1st Floor Barrier North

Email:sales@ajlmachining.com

Tel: +8613522650203