Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

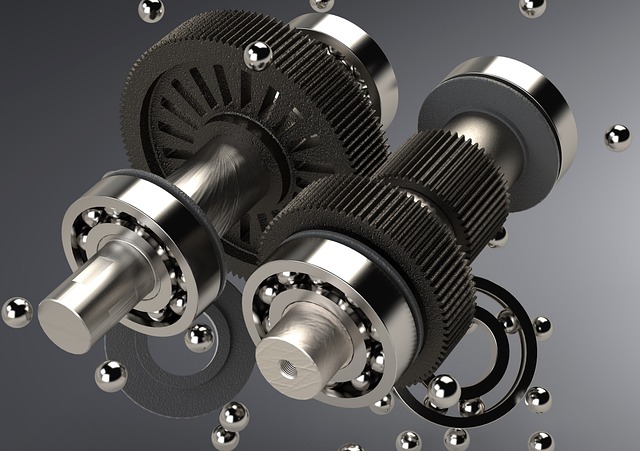

CNC machining plays a vital role in the machinery industry, providing an efficient and precise way to manufacture the metal parts that are essential to the operation of various machines. From simple gears and bearings to complex engine components and hydraulic systems, CNC machining offers the precision, accuracy, and repeatability that is necessary to produce parts that meet exact specifications.

In the machinery industry, CNC machining is used for a wide range of applications, from the production of small and intricate parts to the manufacturing of large and complex components. CNC machining is used in the production of gears, shafts, bearings, hydraulic cylinders, pumps, and other critical components. It is also used in the production of complex engine parts such as crankshafts, camshafts, and cylinder heads, as well as in the manufacturing of hydraulic systems and power transmission systems.

The precision and accuracy of CNC machining are particularly valuable in the machinery industry, where even small deviations from the intended specifications can result in significant malfunctions and damage to the machines. With CNC machining, the production of each part is carefully controlled and monitored to ensure that it meets the exact specifications required for the machine to function properly. CNC machines are capable of producing parts with tolerances as low as 0.001 inches, which is essential for the production of high-precision components.

In addition to its precision and accuracy, CNC machining offers a high degree of flexibility and versatility, making it ideal for the production of a wide range of metal parts for various machines. CNC machines can work with a variety of materials, including steel, aluminum, brass, and copper, as well as exotic metals such as titanium and Inconel. They can also produce parts of varying sizes and shapes, from small and intricate components to large and complex assemblies.

CNC machining is also an efficient and cost-effective way to produce metal parts for machinery. The automation and precision of CNC machining reduce the need for manual labor, which reduces the risk of errors and increases the speed and efficiency of production. CNC machines are also capable of producing high volumes of parts quickly and reliably, which is essential in the machinery industry where the demand for parts can be high.

In conclusion, CNC machining plays a vital role in the machinery industry, providing an efficient, precise, and cost-effective way to produce metal parts for various machines. Its precision, accuracy, flexibility, and versatility make it an essential tool for the manufacturing of high-precision components, complex assemblies, and critical systems. With the continuing development of new technologies and techniques, CNC machining will continue to play an important role in the machinery industry, helping to meet the growing demand for high-quality and reliable machines.

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203