Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

The automotive industry relies heavily on precision and quality when it comes to manufacturing its parts. In recent years, computer numerical control (CNC) machining has become the standard for the production of industrial-grade automotive components. The application of CNC machining in the automotive industry has revolutionized the manufacturing process, making it more efficient and effective than ever before.

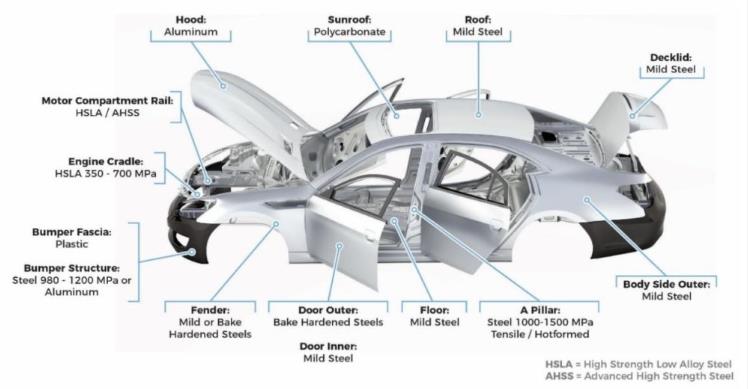

CNC machining is responsible for the manufacturing of a wide range of automotive components, including cylinder blocks, cylinder heads, crankshafts, camshafts, connecting rods, suspension components, bearing caps, and engine housings. The use of CNC technology ensures that these components are produced to exact specifications, and that they are consistent in quality and performance.

At AJL Machining, we specialize in CNC precision parts machining, 5-axis medical components, and CNC machining of aluminum alloy housings. Our team of experts is capable of providing CNC machining for various non-standard equipment processing parts, covering a wide range of industries such as medical equipment, automotive modification, precision parts for auto parts, industrial equipment, photography equipment aluminum alloy shells, and electronic products aluminum alloy shells.

One of the main advantages of CNC machining is its high precision. The process allows for tolerances of approximately 0.01mm, making it extremely unlikely that errors will occur during the manufacturing process. The high level of automation and multi-axis linkage of CNC machines also makes them ideal for manufacturing complex automotive parts with intricate geometries and shapes.

CNC machines are also highly efficient, with short mechanical drive chains and a simple construction that enables high production efficiency. This makes the manufacturing process faster and more cost-effective, with a lower labor intensity and a higher level of consistency in the final product. All of these characteristics make CNC machined automotive parts superior and more reliable than those produced with traditional methods.

In the automotive industry, the failure of a critical component can have serious consequences for the end user. Therefore, the use of CNC machining ensures that these components meet the highest standards of quality and precision. The autonomy of the process makes it extremely unlikely that errors will occur, and the optimum machining settings provide tolerances that meet the exact requirements of the industry.

In conclusion, the automotive industry relies heavily on CNC machining for the production of its parts. CNC machines are known for their high precision, multi-axis linkage, and level of automation. This makes them ideal for the manufacturing of complex automotive parts with high tolerances and intricate geometries. At AJL Machining, we specialize in providing CNC machining for a wide range of automotive components, helping our clients to achieve the highest standards of quality and performance.

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203