Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

The oil and energy industry is a vital sector that requires high-quality and durable metal parts. These parts are used in a wide range of applications, from drilling and exploration to refining and transportation. Two popular manufacturing methods used to create these metal parts are machining and casting and forging.

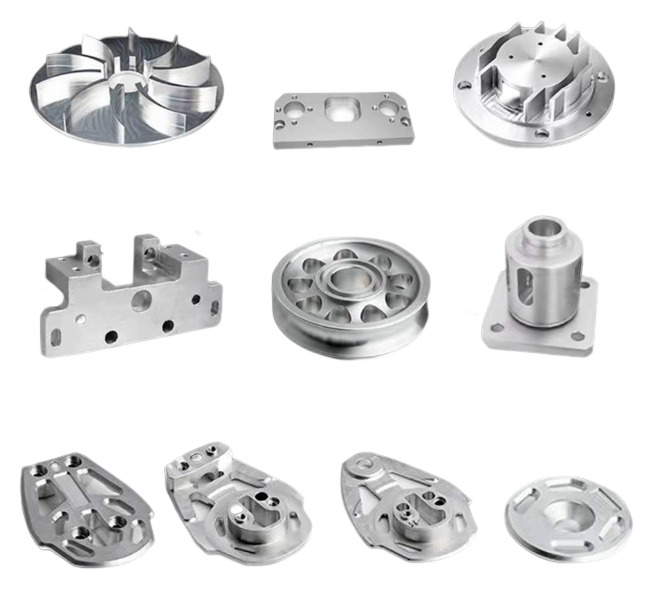

Metal parts machining

Machining is a process that uses a cutting tool to remove material from a workpiece to create the desired shape and size. It is commonly used in the oil and energy industry to manufacture parts with tight tolerances, complex geometries, and high accuracy. Machining can be performed on a variety of materials, including metals, plastics, and composites.

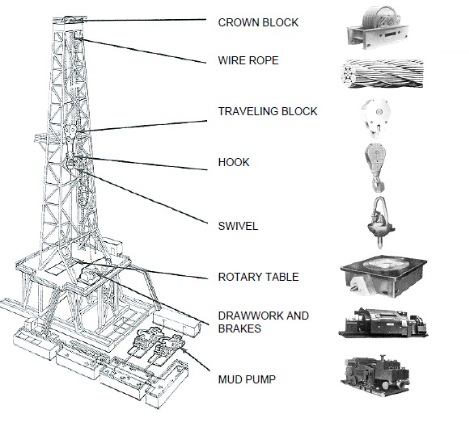

One application of machining in the oil and energy industry is the manufacturing of drilling components. These components, such as drill bits and drill collars, are essential for drilling operations. Machining is also used to create parts for pumps, compressors, and turbines used in the transportation and refining of oil and gas.

Another application of machining in the oil and energy industry is the manufacturing of valves and fittings. These components are used in pipelines, storage tanks, and refineries to control the flow of fluids and gases. Machining is also used to create other critical components, such as pressure vessels, heat exchangers, and other equipment used in oil and gas exploration and production.

Metal parts casting and forging

Casting and forging are two manufacturing processes used to create metal parts by shaping molten metal into a desired shape. These processes are used in the oil and energy industry to create large and complex parts that are difficult or impossible to create using other manufacturing methods.

Casting is the process of pouring molten metal into a mold to create the desired shape. This method is commonly used to create parts such as pump casings, impellers, and other components used in oil and gas production. Casting is also used to create large structural components used in oil rigs and other oil and gas infrastructure.

Forging is the process of shaping metal by applying force to it using a hammer or press. This method is commonly used to create high-strength parts, such as turbine blades, crankshafts, and other components used in oil and gas production. Forging is also used to create large and complex structural components used in oil rigs and other infrastructure.

In conclusion, the oil and energy industry requires high-quality and durable metal parts to operate safely and efficiently. Machining, casting, and forging are essential manufacturing methods used to create these parts. These methods are used to create a wide range of components, from drilling components and valves to pumps and turbines. By using these manufacturing methods, the oil and energy industry can ensure that its equipment is safe, reliable, and efficient.

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203