Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

In the world of industrial piping and plumbing, precision and alignment are critical to ensuring the efficiency and safety of systems. However, in real-world scenarios, achieving perfect alignment between pipes is not always feasible due to constraints such as space, structural design, or installation challenges. This is where offset flanges come into play, offering a practical solution to address misaligned piping. These innovative components are revolutionizing how engineers and contractors approach pipeline construction and maintenance.

What Are Offset Flanges?

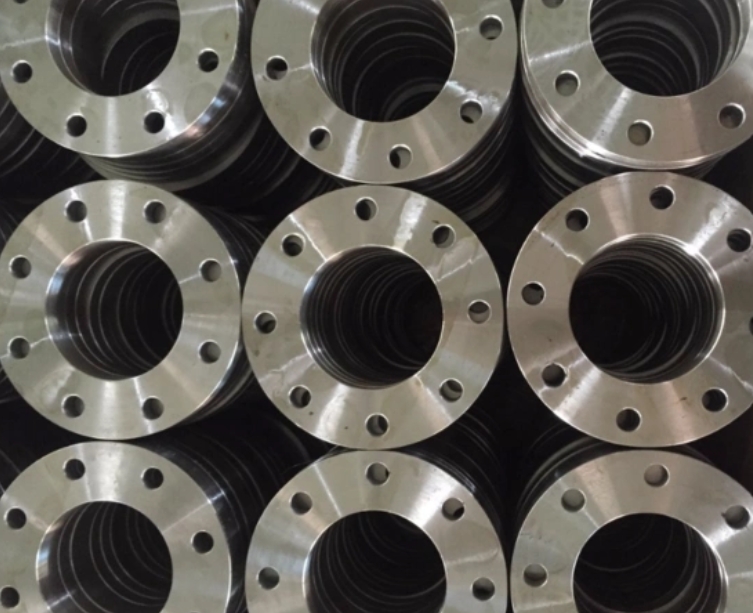

Offset flanges are specialized pipe fittings designed to compensate for alignment issues in piping systems. Unlike traditional flanges, which connect two pipes in a straight line, offset flanges are built with a slight deviation in their bore to adjust for misalignment. This allows them to connect pipes that are slightly off-center without requiring extensive modifications to the system.

Typically available in various materials such as carbon steel, stainless steel, and alloy steel, offset flanges are versatile and can be used in a wide range of applications, including oil and gas, chemical processing, water treatment, and HVAC systems.

Benefits of Offset Flanges

1. Improved Alignment Flexibility

One of the primary advantages of offset flanges is their ability to correct minor alignment discrepancies. Traditional methods of addressing misaligned pipes often involve cutting, welding, or replacing sections of the pipeline, which can be time-consuming and expensive. Offset flanges eliminate the need for such extensive measures, allowing for quick and efficient adjustments.

2. Cost Savings

Using offset flanges can significantly reduce labor and material costs. By avoiding the need for additional fittings, complex welding, or realignment of the entire pipeline, projects can stay within budget while maintaining quality and functionality.

3. Enhanced Safety

Proper alignment in a piping system is critical to preventing leaks and structural stress. Misaligned pipes can lead to uneven pressure distribution, which increases the risk of failure. Offset flanges help ensure a secure connection, minimizing the chances of leaks, cracks, or catastrophic failures.

4. Versatility in Application

Offset flanges can be used in various industries and environments. Whether dealing with high-pressure pipelines in oil refineries or intricate piping networks in water treatment facilities, offset flanges provide a reliable solution for alignment challenges.

5. Ease of Installation and Maintenance

Compared to traditional methods of fixing misalignments, offset flanges are easy to install and maintain. Their design simplifies the process, allowing technicians to quickly adjust and secure connections without extensive training or specialized tools.

Common Applications of Offset Flanges

1. Oil and Gas Industry

In oil refineries and drilling operations, piping systems often extend across vast areas and complex structures. Offset flanges are widely used to connect pipes in tight spaces or in environments where precise alignment is difficult to achieve.

2. Water Treatment Plants

Water treatment facilities often require extensive networks of pipes to transport and process water. Offset flanges ensure that these pipes remain securely connected despite slight alignment variations caused by uneven terrain or structural shifts.

3. Chemical Processing

Chemical plants deal with corrosive and hazardous materials. Offset flanges not only provide alignment solutions but are also available in corrosion-resistant materials, making them ideal for such environments.

4. HVAC Systems

In heating, ventilation, and air conditioning systems, offset flanges are used to connect ducts and pipes that may not line up perfectly due to building constraints. They help ensure smooth airflow and efficient operation.

How Offset Flanges Work

Offset flanges operate on a simple yet effective principle: their bore is designed with a slight offset, typically measured in millimeters or fractions of an inch. This offset allows the flange to be rotated or adjusted to align with a misaligned pipe.

During installation, the flange is bolted to the pipe or fitting, and the offset bore compensates for the deviation. Gaskets and sealing materials are used to create a secure, leak-proof connection, ensuring the system's integrity.

Factors to Consider When Choosing Offset Flanges

Selecting the right offset flange for your application requires careful consideration of several factors:

1. Material Compatibility

The material of the offset flange should match the material of the pipes and the application environment. For example, stainless steel flanges are ideal for corrosive environments, while carbon steel is suitable for high-pressure systems.

2. Pressure and Temperature Ratings

Ensure that the offset flange can withstand the operating pressure and temperature of your system. Most manufacturers provide detailed specifications to guide selection.

3. Size and Offset Dimensions

Choose a flange with the appropriate bore size and offset to match your pipeline's requirements. Accurate measurements are critical to achieving a proper fit.

4. Industry Standards

Ensure that the offset flange meets industry standards such as ANSI, ASME, or ISO to guarantee compatibility and quality.

Installation Tips for Offset Flanges

To maximize the benefits of offset flanges, follow these installation best practices:

Inspect Components: Before installation, inspect the offset flange and pipes for any signs of damage or defects.

Use the Right Tools: Ensure you have the necessary tools, such as wrenches and torque equipment, for secure installation.

Align Carefully: Rotate the flange to find the optimal alignment position before tightening bolts.

Apply Proper Sealing: Use high-quality gaskets and sealing materials to prevent leaks.

Follow Manufacturer Guidelines: Adhere to the manufacturer's specifications for torque settings and installation procedures.

Future Trends in Offset Flange Technology

As industries evolve, so do the technologies used in piping systems. Offset flanges are no exception, with innovations aimed at improving their performance and versatility:

Advanced Materials: Research into new materials such as composite alloys and polymers is leading to more durable and lightweight offset flanges.

Smart Flanges: Integration of sensors and monitoring systems into flanges is becoming a reality, enabling real-time monitoring of alignment and performance.

Sustainable Solutions: Manufacturers are focusing on eco-friendly materials and processes to reduce the environmental impact of flange production.

Conclusion

Offset flanges are a game-changing solution for addressing misaligned pipes in a wide range of industries. Their ability to provide flexibility, cost savings, and enhanced safety makes them an indispensable component in modern piping systems. By understanding their benefits, applications, and proper installation techniques, engineers and technicians can harness the full potential of offset flanges to improve the efficiency and reliability of their projects.

As technology continues to advance, offset flanges are set to become even more versatile and innovative, ensuring their place as a critical tool in industrial piping solutions for years to come.

About AJL Machining:

AJL Machining is a professional and industry-leading one-stop workshop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production. Our competitive edge is our ability to ensure that all of your parts are produced according to specifications, within budget, and delivered on time to meet your evolving demands. Presently, we serve over 80% of our business to multinational corporations in China, as well as overseas customers.

To learn more, please don't hesitate to contact us via email at sales@ajlmachining.com, or visit our website at www.ajlmachining.com

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203